C-Article Procurement

The number of suppliers as a cost driver

Are you familiar with the Pareto principle? This massively influences your c-item procurement.

Find out!

Efficiently Manage C-Items – Keep Costs, Transparency, and Control

C-items are small, often inexpensive materials that companies need on a daily basis. Although individual costs may seem low, expenses can quickly add up when there are no centralized procurement processes in place.

The Pareto Principle in Action

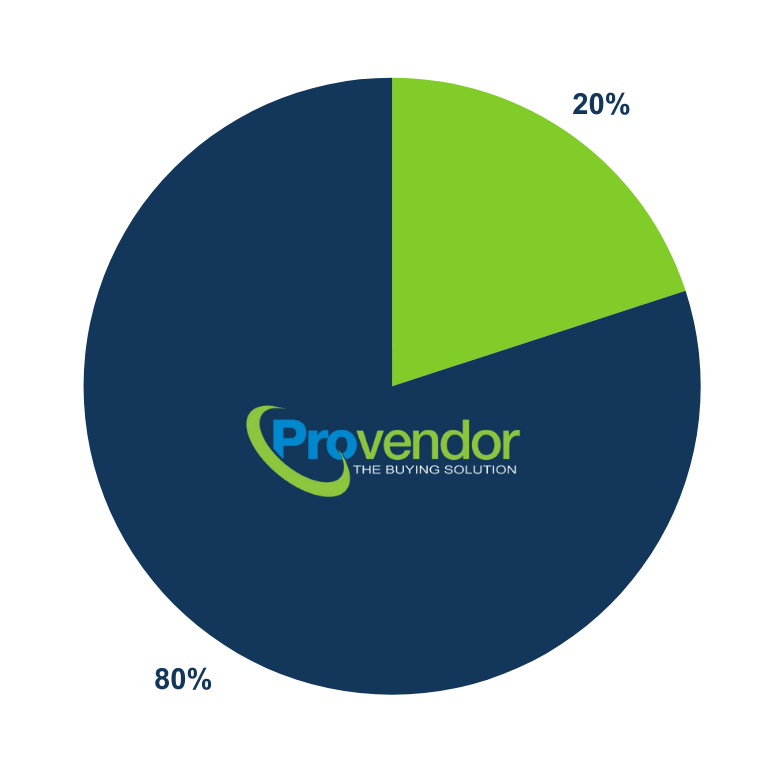

The Pareto principle shows: focus on the 20% of suppliers that account for 80% of your purchasing volume … and let us handle the rest!

The 80% of suppliers that only make up 20% of your purchasing volume often generate a significant portion of administrative costs (approximately €500–1,500 per supplier per year). Uncoordinated orders lead to high administrative effort, lack of transparency, and unnecessary expenses.

Strategic C-Item Management

With a targeted strategy for C-items, companies can work more time- and cost-efficiently, optimize inventory, and clearly define responsibilities. Provendor supports you in centrally managing all C-items, standardizing processes, and optimizing orders—without individual departments losing oversight.

Gain time and focus on what really adds value!

How Does Provendor Optimize Your C-Item Procurement?

Provendor offers tailored solutions for C-item procurement

All orders go through a standardized process.

Responsibilities and the status of each order are visible to everyone.

Provendor manages recurring C-item orders, reducing your administrative effort.

View expenses, consumption patterns, and trends at any time.

C-Item procurement made easy

As a full-service supplier, we take over your suppliers and thus relieve you of everything that causes effort and costs in procurement: from inquiry to delivery.

Reduce the number of your suppliers efficiently and cost-effectively now!

FAQ

C-items are smaller materials used daily in a company. Individually, they may seem inexpensive, but overall costs can be high if they are not managed centrally.

Through centralized processes, clear workflows, transparent inventory, and a structured ordering system.

It ensures that budgets, responsibilities, and stock levels are always clear and traceable, minimizing costs and effort.

-

Decentralized Orders: Each department purchases separately without coordination.

-

Lack of Processes: No clear procedures or responsibilities.

-

Time Pressure: Urgent requests lead to spontaneous purchases.

-

Disorganized Inventory: No consistent stock management.

-

High Transaction Costs: Many small orders create unnecessary effort.

-

Lack of Transparency: Nobody knows exactly what has already been purchased.

Do you have any further questions? Contact us—we are happy to assist you and address all your concerns.