The Single Vendor Model: Interview with Stefan Knorsch (Scalue am 10.05.2023)

Mr. Knorsch, today we are focusing on the topic of the one vendor model. First of all, therefore, the question: What does one actually understand by this term?

The term one vendor model , also known as the single vendor model, refers to a model in which only one supplier is responsible for supplying the selected goods or service. This model significantly reduces the number of suppliers and therefore the associated time and costs to manage suppliers.

What is your personal enthusiasm for the topic and how important do you think it is for the future?

As the Managing Director of Provendor and a purchasing expert for many years, I have personally experienced many situations in which companies have faced major challenges in the procurement of materials and services. In particular, the complexity and time involved in managing a large number of suppliers was often a major burden for companies. For this reason, I decided to found Provendor and support companies with our comprehensive procurement services.

One professional event that particularly motivated me to start Provendor was a situation in which I myself was the purchasing manager for a company and we were experiencing various difficulties due to the large number of suppliers.

In order to process the endless number of orders, an enormous amount of time had to be spent, which was then lacking to optimize the cost prices and ensure the quality of the deliveries. By implementing a one vendor model, we could have drastically reduced the number of suppliers and thus lowered our procurement costs. In addition, we would then have had time for strategically important purchasing tasks. This situation was an important starting point for me to help companies with similar procurement challenges.

How are companies currently overcoming the challenges and what best practices can you tell SCALUE customers?

Today’s procurement challenges are more complex than ever. Companies are faced with managing a multitude of suppliers and materials, negotiating price and quality, processing purchase orders and monitoring delivery performance, taking into account ESG and LkSG issues. However, many companies are unaware of the “shadow costs” that arise from procurement complexity. These indirect costs can be enormous and significantly impact a company’s profitability. They include, for example, costs for too many suppliers or poor cost prices due to lower purchasing volumes per supplier, missing order processing and delivery routines, lengthy approval processes, recording and maintaining master data, and many more.

It is therefore crucial that companies become aware of these shadow costs and take effective measures to reduce them. Best practices include reducing the number of suppliers by implementing a one vendor model, optimizing order fulfillment processes, monitoring delivery performance, and last but not least, negotiating prices and terms. Companies should also consider using technologies such as procurement analytics and AI-based solutions to automate and optimize the purchasing process.

What are the potential consequences if companies do not take action?

If companies do not take action, they may face increased time and therefore higher costs for supplier support, unpredictable delivery bottlenecks, quality problems and poor cost prices. All of this leads to a loss of competitiveness that should not be underestimated.

How does Provendor GmbH currently support companies and what are the unique advantages for companies that already work with Provendor today? Can you explain this to us with a practical example?

Provendor GmbH supports companies through a wide range of procurement services, such as supplier reduction, spot buy implementation, C-item sourcing, operational support and procurement services, support of unattended material groups, mystery buying and maverick buying prevention. The unique advantage for companies working with us is the direct support provided by our experienced staff, ensuring fast and reliable supply to our customers. A practical example would be the implementation of a one vendor model for a mid-sized company that, by working with Provendor, was able to reduce its number of suppliers by 50%, thereby reducing its procurement costs by more than 30%.

Is it possible to set up an ROI calculation for one vendor model project?

Yes, it is possible to set up an ROI calculation for a one vendor model project. The ROI calculation can be performed based on the expected cost savings and the cost of using the one vendor model.

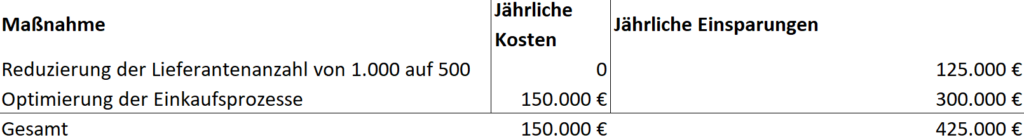

In this example, it was assumed that reducing the number of suppliers and optimizing purchasing processes would lead to total annual savings of €425,000. The running costs amount to 150,000 € p.a.. In this example, savings can be seen from the first order in the 1-creditor model. The savings achieved by professionalizing procurement and bundling requirements have not even been taken into account.

It is important to note that this sample calculation is only an estimate and that actual costs and savings may vary by company and situation.

How long does it take to implement a one vendor model project and what can companies expect from a collaboration?

Companies that enter into a collaboration with an experienced procurement service provider such as Provendor GmbH can benefit from a quicker and smoother transition, as well as from the service provider’s expertise and experience in the field of procurement services. Our clients can benefit from fast project implementation, clear communication and ongoing support from our experienced staff. We work closely with our customers to understand their individual requirements and needs and provide a customized solution tailored to their specific needs.

This interview was first published on Scalue Insights on 10/05/2023.